|

|

Alucushion Steel Building Projects |

Think Precision Engineering Think Steel Building Projects |

|

|

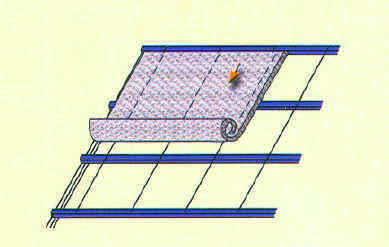

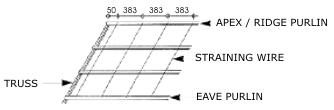

Alucushion / Bubblefoil® FR (Fire retardant grade) White (Code 2906) and Alucushion® FR (Fire retardant grade) Double-sided (Code 1983). Alucushion / Bubblefoil® FR (Fire retardant grade) is manufactured by a continuous lamination process of low-density polyethylene and aluminium foil with sealed bubbles of air between the two outer laminates. The thousands of individually celled air bubbles created during the manufacturing process form a column of immobilised dry air, effectively countering heat loss through convection and conduction. Add to this the low emissive and high reflectivity of the aluminium foil surface, and it's advantages as a heat transfer barrier become obvious. |

|

Alucushion / Bubblefoil®

FR (fire retardant grade) is the cost effective solution for most roof

insulation applications, and has the following value added benefits:

Properly installed under normal environmental conditions, Alucushion / Bubblefoil® FR will last the lifespan of the roof under which it has been installed. Alucushion FR is tested and evaluated according to SABS 1381 (Materials for Thermal Insulation of Buildings) Part 4: Reflective Foil laminates, rolls, sheets and sections.

|

|||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||